Originally Published 11-3-2020

Solar design can be overwhelming, but over the past 35 years, we’ve designed a process that makes developing your next product efficient, collaborative and cost-effective.

PowerFilm’s solar technology and capabilities are versatile, allowing us to provide custom solutions across multiple industries and markets, including government and DoD, transportation, IoT, and many others.

Watch the video below to learn more about PowerFilm’s custom solar capabilities.

In today’s post, we’ll discuss the steps of our design process, including:

- Concept Development

- Design Review

- Prototyping

- Field Testing

- Pilot Production

- Volume Production

Take this blog post with you!

Concept Development

What your solar solution looks like depends mostly on power and environmental requirements.

How much energy does your device consume?

The blog posts below describe creating a power budget and characterizing devices’ power consumption.

How To Size A Solar Panel For Your Battery

Calculating Your Power Budget

How does the application environment affect a solar solution?

The blog posts below describe critical environmental factors during the concept development phase.

Seasonality of Solar

How Does Temperature Affect Solar Panels?

How Does Partial Shading Affect Different Types of Solar Panels

Outdoor vs. Indoor Solar: The Key Differences

Considering these factors will provide insight into the right solar technology, size, and characteristics needed for your application.

Our standard products offer a great starting point and expedite the custom design process.

For low-power applications, our Electronic Component Solar Panels and Solar Development Kits are an excellent start. These small and medium-sized panels serve many indoor and outdoor IoT solutions, replacing or extending battery life.

For medium-high power applications, check out our high-efficiency semi-flexible solutions. These panels currently serve many transportation, marine, and fixed and semi-permanent mount applications.

For ultra-rugged, shade-tolerant, lightweight, and portable applications, our thin-film amorphous silicon Foldable and Rollable products are a great fit.

Is crystalline silicon or amorphous silicon the right choice for your application? This blog post lays out the benefits of each solar technology so you can make the best decision.

With many different types of IoT devices and low-power electronics, we don’t always have a standard design that meets customer’s needs. Luckily, we produce custom panels built to your specific requirements.

Our Custom Solar Panel Design Tool is a convenient way for developers to understand the sizes and options available.

Finally, our expert engineering staff designs/consults on all aspects of a solar power solution, including charge controllers, Power Management ICs (PMIC), storage elements, and optimizing device power consumption.

During this stage, PowerFilm works with the customer to go over everything the solution may need electrically and mechanically.

Design Review

The next step is to use all requirements and information gathered during concept development to create and propose a solar solution.

During this phase, we define all relevant panel characteristics that meet your unique application needs, including size, shape, PV technology, flexibility, substrate, mounting mechanism, wiring, connectors, contacts, electronics, weatherproofing, surface finish, aesthetics, testing, and more.

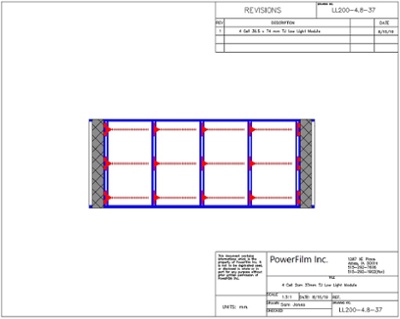

This process generally takes the form of a 2D CAD drawing of the panel concept with defined electrical and mechanical specifications.

Design proposals include prototype and production pricing and any engineering time required for the project.

You can review, ask questions, and offer changes or modifications until you are satisfied with the design proposal.

Prototype

*Photo courtesy of Plastic Logic

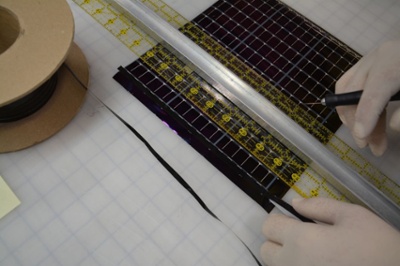

After approving the design proposal, PowerFilm engineers begin building and assembling functional prototypes.

Depending on the design, prototypes may be ‘built by hand’ and not look exactly like the production unit. Changes between prototype and volume production are clearly defined in the product proposal.

Prototype assembly usually takes 2-3 weeks for simple builds but could take longer for more intricate designs or custom materials.

Field Testing

With functional prototypes complete, testing in the application environment is critical in determining a solar solution’s performance.

Things to test and verify include:

- Adequate power generation under expected and variable conditions

- Ease of installation

- Viability of weatherproofing (if required)

- Thermal stability

- Power consumption of the end device

- Mechanical stability and function

Pilot Production

Pilot production allows us to refine the manufacturing of your specific design and prepare for volume production.

During this stage, we test and tweak new equipment, jigging, and processes related to the solar design.

Larger scale field testing is incorporated into this step, which can catch and resolve variation issues before launching the product at scale.

Volume Production

Volume production is the last step in the design process, but innovation always continues.

Once your solar solution enters production volume, we refine our processes to manufacture solutions better and more efficiently.

We provide the best possible solutions for our customer’s needs. As we expand our technical capabilities, we continue working with customers on next-generation products and enhancements to current designs.

Custom solutions are our business and have been for the past 35 years.

Working with PowerFilm helps you get to market faster with a product built to your exact requirements.

Are you ready to take the next step in your product’s journey?

Contact us, and let’s get started today.

Take this blog post with you!