Which Portable Solar Technology Is Best: A Primer

Imagine you’re a business owner responsible for keeping your company’s operations running smoothly, even in power outages or natural disasters.

You need a reliable and portable power source that can keep your equipment up and running, no matter the circumstances.

That’s where portable solar technologies come in.

Unfortunately, selecting the best solar technology to solve your business problems is anything but straightforward.

Today’s post will help you make an educated decision on which solar technology is right for you by comparing the following:

- Flexibility

- Durability

- Portability

- Power/weight ratio

- Temperature coefficient

- Variable/low-light performance

- Efficiency

- Cost

We’re going to review three specific technologies in detail:

- Crystalline Silicon (c-Si)

- Amorphous Silicon (a-Si)

- Copper-Indium-Gallium-Selenide (CIGS).

- We will also briefly address two other solar technologies: Organic (OPV), an emerging technology in the commercial space, and Gallium Arsenide (GaAs), a highly efficient but costly solar technology.

Take this blog post with you!

Before we begin, let’s define the categories we will use to compare each technology:

Flexibility: Ability to be flexed (important in design integration), up to and including rolling or folding for storage.

Durability: Resistance to damage from dropping, physical impacts, rough handling, and exposure to elements.

Portability: The ability to transport easily.

Power/Weight Ratio: Power generated per lb/kg (important for weight-constrained designs and portable applications).

Temperature Coefficient: How each technology is affected by heat. This impact is self-correcting under normal circumstances.

Variable/Low-Light: Ability to harvest energy when partially shaded or in indoor or low-light environments.

Efficiency: A laboratory measurement of how solar technology converts light to energy in specific environmental conditions, called Standard Test Conditions (STC, 25C with 1000 W/m2 at AM1.5).

Cost: The expense of the technology relative to other solar options.

Flexibility

Crystalline Silicon: Portable panels come in several formats. Typical substrates for these panels include metals such as aluminum, plastics such as HDPE, Tedlar or PET, or composites like fiberglass or carbon fiber. Depending on the specific monocrystalline cell technology used and the substrate, a crystalline silicon panel can be rigid and unable to flex without breaking or capable of flexing around an 18-inch radius without breaking. PowerFilm panels are commonly backed on fiberglass and are semi-flexible to a degree before cracks and damage occur.

Amorphous Silicon: Incredibly flexible and can be rolled or flexed without damage. Depending on the encapsulation thickness, this technology can wrap around a pencil without damage.

CIGS: Can be manufactured on a flexible plastic substrate and, depending on the cell manufacturing process and encapsulation, can be nearly as flexible as amorphous silicon.

Durability

Crystalline Silicon: Quite brittle but more resilient with the proper encapsulation. Crystalline technology is susceptible to damage when dropped or handled roughly, even with an ideal encapsulation. Maxeon has a full-contact backplane, which adds rigidity/durability. The most resilient panels feature interdigitated back contact cell technology. These monocrystalline cells have plated copper fingers interlaced on the back of the cells, creating a dense network of positive and negative contacts, allowing for power collection from cells even after damage. They improve durability by only requiring connections from cell to cell along the edges, so unlike standard busbar cells, there are no soldered bus bars across the front and back of the cells to put stress on and break the silicon during flexing.

Amorphous Silicon: Very resilient to damage due to a monolithic construction, which means the solar modules are fabricated and interconnected on a single piece of plastic without tiling or soldering to connect cells. If a portion of the panel is damaged, that area shuts down, but the remainder will continue collecting energy. When damaged, the performance of this material is superior to any other technology.

CIGS: This technology is sensitive to moisture and humidity and requires specialized barrier films as encapsulants to maintain a long lifetime. When something impacts the barrier films, this can cause cracks in the barrier, leading to moisture ingress and shortening the panel’s lifetime.

Learn more about amorphous silicon’s extreme durability.

Portability

Crystalline Silicon: Portable to a point due to weight and lack of flexibility. Smaller panels can be taken with you, but often, crystalline panels are designed for static installations. PowerFilm offers designs to minimize weight and improve the portability of cSi products.

Amorphous Silicon: Incredibly portable and ideal to be folded, rolled, and provide power for mobile applications.

CIGS: Although lightweight and rollable, depending on the process, panels from some manufacturers will degrade significantly and irreversibly during long-term storage. This doesn’t suit portable applications where panels may be stored for long periods between uses.

Power/Weight Ratio

Crystalline Silicon: Semi-flexible crystalline panels have higher power-to-weight ratios than traditional rigid framed panels. A typical foldable panel is 50W/kg, whereas specific PowerFilm aviation designs have achieved 240W/kg.

Amorphous Silicon: Achieves exceptionally high power-to-weight ratios using ultra-lightweight substrates and encapsulants. For specific PowerFilm aviation designs, where weight is crucial, it can reach beyond 500W/kg.

CIGS: While not the highest, CIGS solar technology is quite efficient regarding power/weight.

Temperature Coefficient

The temperature coefficient of a solar cell refers to how the output of the cell changes with an increase or decrease in temperature. Typically, as a solar cell increases in temperature, the power output will decrease, and the power output will increase as temperature decreases. This effect happens instantaneously and is entirely reversible.

Crystalline Silicon: Most affected by heat and degrades 0.40% per degree C over 25C. (1) Maxeon’s interdigitated back contact cells are significantly better than the standard silicon cells, thanks to the thick-plated fingers on the back side of the cells. Their temperature degradation is 0.27% per degree C.

Amorphous Silicon: Affected less by heat than other technologies and degrades 0.16% per degree C over 25C. (1)

CIGS: CIGS, much like crystalline, is greatly affected by heat and degrades 0.30% per degree C over 25C. (1)

Learn more about how temperature affects different solar technologies.

Variable/Low-Light Performance

Light level is a critical factor in the performance of a solar panel. Light levels range from 200 lux or less indoors to 130,000 lux outdoors on a bright sunny day. At high light levels outdoors, defects within a cell do not affect performance significantly. As the light level decreases, defects can dominate the overall performance. Typical defects are shunts, which are pathways for power to be consumed internally by the solar cell so that it cannot be harvested and used by a device. Some technologies have more defects, and some processes, such as laser cutting, inherently create defects that reduce performance when a panel is shaded or used indoors.

Crystalline Silicon: High-quality whole cells, like the Maxeon wafer we use in Soltronix products, have excellent low-light performance, while low-quality and laser-cut cells have much poorer performance.

Amorphous: Has great low-light or indoor performance, collecting more energy in lower-light situations than other technologies. PowerFilm Indoor Solar material performance is guaranteed in indoor light down to 200 lux and will work below that light level.

CIGS: CIGS has poor indoor performance due to the inherent leakage in the technology. It is only used in outdoor full sun applications. In addition, it has a very high series resistance due to the number of cells that have to be connected.

Learn more about how shade affects different solar technologies.

Efficiency

Crystalline Silicon: 18-22% and up to 24%+ at the top end. This value can drop to 8-15% once cells are cut to make small, sub-25W panels.

Amorphous Silicon: A real-world performance average of 6% with lab results up to 12%.

CIGS: 12% is common, with higher efficiencies possible in lab conditions.

Cost

Crystalline Silicon: Due to an ever-increasing scale, the cost of crystalline solar panels continues to drop, making it the least expensive solar technology.

Amorphous Silicon: Amorphous solar panels are expensive due to limited manufacturers and scale.

CIGS: Due to the moderate scale and limited manufacturers, the cost of CIGS is relatively high.

General Advantages

Crystalline Silicon: Depending on the manufacturer, crystalline solar panels can be quite efficient and cost-effective, making them an ideal solar technology for static or relatively static installations with full sun exposure that don’t require extreme durability or flexibility. This technology is also used in applications where the available area is at a premium due to its high power output per area.

Amorphous: Amorphous is ultra-thin, lightweight, highly durable, flexible, and portable. It is ideal for applications that require extreme durability and flexibility. a-Si is the perfect technology for custom projects and can be integrated into designs more easily than rigid technologies.

CIGS: Flexibility, medium cost, and moderate efficiency. Its primary use is as a low-cost solution for satellite systems.

General Disadvantages

Crystalline Silicon: As a rigid solar technology, crystalline is not ideal for portable applications where panels constantly move and can’t always be handled carefully. Cells are prone to cracking, and entire panels can stop functioning. Expert design, materials, and construction are required to ensure crystalline panels can withstand demanding portable applications. Crystalline silicon panels with excellent durability can be made for specific portable applications, but not all are equal. Vet c-Si panels in your application to ensure they will meet the durability requirements.

Amorphous Silicon: Due to manufacturing scale, amorphous is more expensive than other technologies and requires more area to generate the same power (significant for space-constrained applications).

CIGS: CIGS panels require “sun-soaking” before reaching their rated output. Long-term storage can permanently damage these panels since CIGS material degrades when not exposed to light. Additionally, CIGS technology is prone to damage from impacts leading to moisture/humidity damage in the long term.

Gallium arsenide (GaAs)

While exceedingly expensive, gallium arsenide can be made in a flexible, portable, high power/weight ratio format. This technology is only viable for applications where costs are not a driver and someone is looking for a lightweight solution with the most power possible in a given area. GaAs is viable for high-cost/performance applications such as small UAVs and satellites.

Organic (OPV)

Only during the past few years has this emerging solar technology become viable for specific applications. OPV technology can be flexible and has excellent low light harvesting capability down to 50 lux or less. It degrades when exposed to high light levels outdoors and humid/wet environments. It also experiences a long-term degradation similar to CIGS when stored in total darkness. Currently, it costs more than amorphous silicon but promises a path to lower costs in the future.

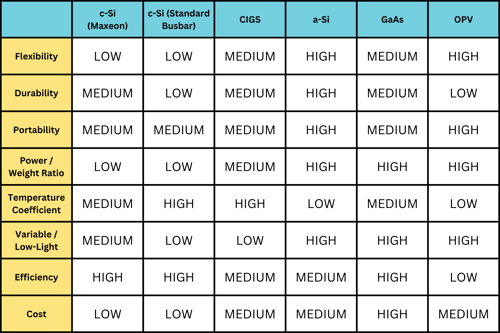

Solar Comparison Chart

Solar is more than a single technology. Each technology comes with its own set of strengths and drawbacks.

Depending on the application, several solar technologies can satisfy your particular needs.

PowerFilm Solar has been developing and honing the manufacturing of amorphous silicon for over 35 years and also offers a host of custom crystalline solar solutions.

We would love to hear more about your power needs, suggest solutions we can create, and help determine what is best for you.

Contact us today, and let’s start a conversation.

Take this blog post with you!

Sources:

(1) Outdoor performance of organic photovoltaics: Diurnal analysis, dependence on temperature, irradiance, and degradation p.9

(2) Outdoor Performance of a Thin-Film Gallium-Arsenide Photovoltaic Module p.4

(3) National Renewable Energy Laboratory

(4) Ruiz Raga, Sonia & Fabregat-Santiago, Francisco. (2013).Temperature effects in dye-sensitized solar cells (p.2333)

(5) Franhofer ISE Photovoltaics Report p.26