Originally Published 4-26-2019

Through the years, we’ve fielded thousands of solar-related questions.

One that consistently comes up is the possibility of collecting solar energy through glass.

In today’s post, we explore if this is possible, its limitations and which solar technologies perform best with a glass barrier between them and the sun.

Additionally, we will uncover what, if any, are the differences in collecting solar energy behind windows in buildings and windows in a vehicle.

Take this blog post with you!

Windows have multiple functions, and despite their appearance of high transparency and high color rendering index, there is still a significant amount of light that is not transmitted through a window.

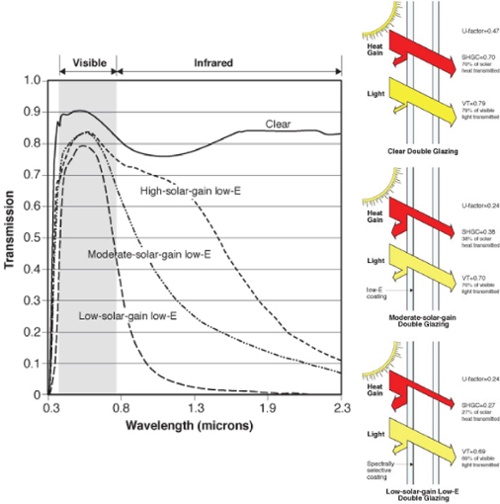

Figure 1 shows the transmission of common types of building window glass. Transmission for clear glass is less than 90% of the possible light based on the ideal angle of light incidence.

The light transmission can be much lower for high-efficiency Low-E windows, especially in the infrared.

This can be especially problematic for solar technologies such as CIGS, perovskites, polycrystalline silicon, and monocrystalline silicon since about 50% of the light they collect is from wavelengths between 800-1200nm.

Amorphous silicon collects light from wavelengths between 400 – 700nm, resulting in far less rated power loss behind a window than with other technologies.

Figure 1: Window transmission compared to wavelength for various building window glass options.

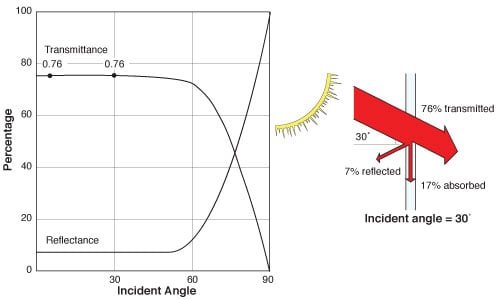

In addition to loss due to window transmittance, there is also loss from window reflection as the angle of light incident on the window changes, as shown in Figure 2.

The transmittance of the glass remains relatively constant up to about 60 degrees, at which point it drops rapidly due to increased reflection off of the window's front surface.

Figure 2: Transmittance/Reflectance of a window compared to the angle of incident light.

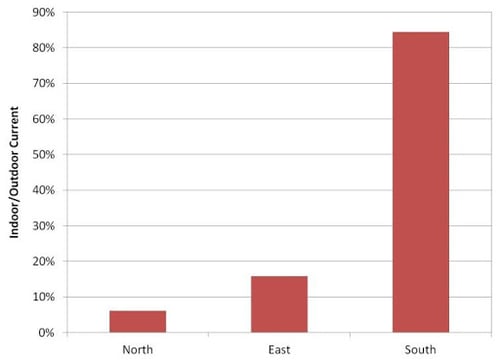

Figure 3 shows how an amorphous silicon panel would perform if placed behind clear window glass on a building compared to a south-facing panel vertically mounted on the outside of a building.

These measurements were taken in September at a longitude of 42 degrees north at solar noon, so the sun's altitude was about 53 degrees from the horizon.

The figure shows that the amount of diffuse light collected through the window on the sides of the building is quite low, 7-15% during ideal sun conditions.

Early in the morning, a panel mounted on the east side of a building will produce more power, but as the day progresses, its power production will drop below 15%.

The panel on the north side of the building will rely on diffuse light throughout the day, keeping its power yield quite low.

Figure 3: Amorphous silicon power production at solar noon through building window glass.

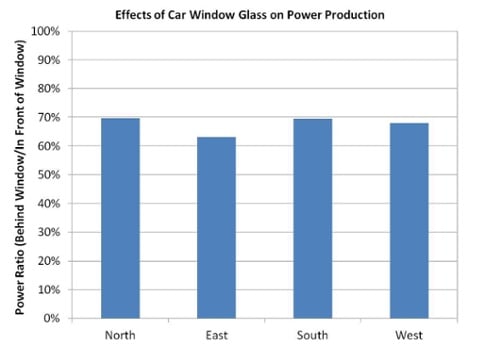

A final comparison is made for the solar performance of a panel placed in the window of a vehicle compared to sitting flat on the hood of the vehicle, as shown in Figure 4.

This shows that placing the panel behind the windshield will reduce the light received by the panel by 30-40% as a best case.

If the window is tinted, the results will be even worse. Even low levels of tinting will have a significant impact on light collection.

For a crystalline silicon panel mounted below a tinted sunroof, the available light could easily be 5-8% of the light on the vehicle's roof.

Figure 4: Power generated through the windshield of a vehicle compared to a panel placed on the hood when the vehicle is facing in each of the cardinal directions.

In summary, it is possible to collect solar energy through glass, but the amount of energy will be significantly less.

If you plan to install a panel behind a window or other glass barrier, amorphous silicon is ideal because it can harvest more energy through glass than other technologies.

Want to learn more about our perception of light and how much solar is available in different environments?

Check out our post, Solar Intensity: Looks Can Be Deceiving or Outdoor vs Indoor Solar: The Key Differences.

Interested in learning more about PowerFilm’s custom capabilities and how we can walk through all the different variables to account for when designing your next solar product?

We would love to start a conversation.

Whether addressing potential pitfalls in design, environmental effects and limitations or the best product encapsulation, we know custom solar and will help take your product plans to full-scale production.

Contact us, and let’s get started today.

Take this blog post with you!