IoT wearables generate lots of buzz in the tech community, often accompanied by insane projections of exponential growth.

Why haven't these projections been realized?

Power is a significant hurdle.

Take this blog post with you!

To truly succeed, wearables must be so inconspicuous that users forget they are even there. Battery life, bulk, and the limited form factor of traditional battery solutions make that very difficult to achieve.

Energy harvesting with optimized solar cells (even indoors) can solve this power dilemma in many practical use cases, but not just any PV cell fits the bill.

Wearables are a unique use case for solar energy harvesting. The combination of mobility, rapidly changing light levels, and highly irregular shading/lighting require a careful selection of both the proper PV module and the correct energy harvesting power management IC (PMIC).

The first thing you will need is a single cell PV module.

Solution for Irregular Lighting

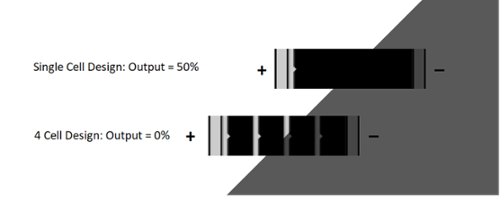

Single-cell PV modules perform well under irregular shading patterns. A single cell panel will output 50% when half-shaded, whereas a multi-cell panel may output nothing.

Irregular lighting is ubiquitous for a wearable device. Shading can be complicated to predict, especially for indoor IoT applications where wearables may experience an array of different environments, positions, and orientations dynamically.

Single-cell solar modules excel under adverse lighting conditions and random shading patterns. Multi-cell panels may output nothing if even a small portion of the module is shaded or covered.

This is explained by Kirchoff's current law, which states that electricity flowing into any point on a circuit must equal the electricity flowing out. Said another way, the flow of electricity through a single wire is the same at all points on that wire. Breaking the wire at any point will not allow current flow.

This concept remains true for solar cells. Multi-cell panels are wired in series, like one single long wire. Shading or covering one cell will block current from flowing through the entire panel, i.e., the panel will output nothing.

Conversely, shading portions of a single cell panel will not block current from flowing. Imagine blocking half of a water pipe. Water will still flow through the half that is not blocked. The same holds for single-cell PV. When shaded, the output is only reduced by the shaded amount, as demonstrated in the photo above.

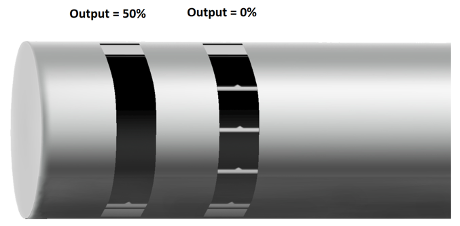

Solution for Curved Surfaces

Curved surfaces often cause uneven shading across a panel. The single-cell module will only be reduced by the shaded amount, whereas the multi-cell panel may output nothing.

Many wearable applications have benefitted from advances in flexible circuits and PV cells which can wrap around and follow the contour of non-flat surfaces.

This also causes irregular shading patterns, which we learned above, render multi-cell panels useless.

The output of a single cell panel on a curved surface will only be reduced proportionally by the area that is shaded. If 25% is shaded, the output will only drop by 25%.

Hidden Benefit – Increased Efficiency

With more interconnects, multi-cell panels have greater inactive space that does not contribute to power generation.

A single cell design could output up to 10% more power per area than a multi-cell design of the same form factor. This simple design change has a significant impact on panel performance, which can be vital for applications that need every mW of power they can get.

Boosting DCDC power management IC

The second piece of the solar wearable puzzle is using the proper energy harvesting PMIC that can boost the low input voltage of a single cell module up to charge a battery (or capacitor) AND has a quick Maximum Power Point Tracking (MPPT) algorithm.

Light level seen by a wearable can change often and rapidly. If a PMIC cannot respond to these changes, it could result in poor energy harvesting performance.

The AEM10900, from e-peas, is a new energy harvesting PMIC designed specifically for single-cell PVs. It provides expanded control over the MPPT timing and other valuable features, such as an I2C interface and an integrated power meter.

Putting It All Together

The highly durable, thin, and flexible nature of PowerFilm's PV material makes it the ideal energy harvesting solution for the next generation of wearable electronics.

We can design and provide single-cell modules in a wide range of sizes and even integrate it directly into fabric.

Contact us to learn more about what's possible and how to solve your wearable battery problems with a single cell PV module.

Take this blog post with you!