Originally Published 4-27-2023

Powering the Future of Sustainable Fleet Transportation

Fleet operators are always looking for ways to reduce downtime, control energy costs, and improve sustainability in electric vehicle fleet operations. GEM's low-speed electric vehicles (LSEVs) are already a smart solution for campuses, resorts, and business parks—but what if they could do even more?

That’s where solar comes in. Working with PowerFilm, GEM developed a powerful, custom solar upgrade that helps fleet managers extend range, minimize reliance on charging infrastructure, and visibly demonstrate their commitment to clean energy.

Take this blog post with you!

The Challenge: Solar Charging for Commercial Electric Vehicles

GEM vehicles often operate in environments where traditional charging infrastructure is sparse or inconvenient. Between frequent stops and long hours parked outdoors, these vehicles were prime candidates for solar charging—but only if the system could meet the demands of commercial operations.

GEM needed a solar partner who could design a solution for low-speed electric vehicles that was powerful, easy to integrate, and scalable across their lineup.

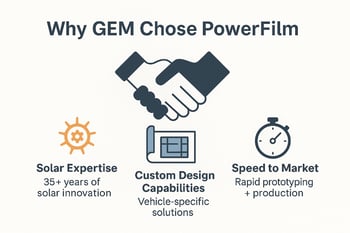

Why GEM Chose PowerFilm as Their Solar Partner

GEM wasn't looking for an off-the-shelf solar panel. They wanted a partner who could:

- Engineer a high-efficiency, vehicle-specific solar solution

- Deliver volume production quickly and reliably

- Ensure easy installation and long-term durability for commercial fleets

PowerFilm met every requirement. With over 35 years of solar innovation and a reputation for rapid prototyping, we were ready to deliver.

.png?width=600&height=287&name=Blog%20Post%20163%20-%20Sven%20Quote%20(Transparent).png)

Designing a Custom Solar Kit for GEM Low-Speed Electric Vehicles

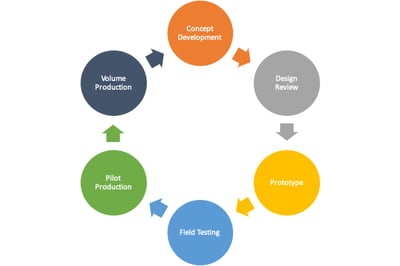

Our collaboration began with hands-on prototyping. PowerFilm received a GEM e4 vehicle to test and develop a solar charging system tailored to GEM’s specific design.

How do we go from prototype to production-ready? Read about our custom solar design process.

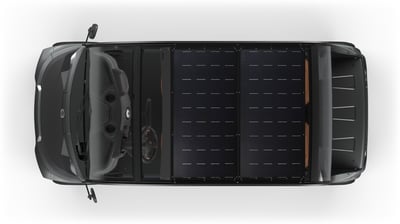

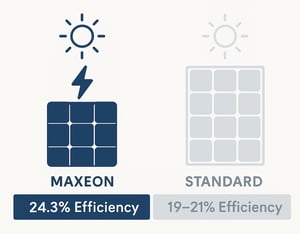

After several design iterations, we created a modular solar kit built around 120W Maxeon solar panels.

The Custom Solar Design Process

Each panel features Maxeon’s high-efficiency back-contact solar cells, delivering reliable, high-performance solar power for commercial electric vehicles.

They include:

- UV- and heat-resistant ETFE lamination for durability

- Lightweight fiberglass construction to minimize vehicle weight

- Automotive-grade, custom-length wrapped cabling for easy installation

Learn more about why we use Maxeon's high-performance solar cells.

.png?width=600&height=290&name=Blog%20Post%20163%20-%20Brad%20Quote%20(Transparent).png)

The scalable design includes:

- Two 120W panels (240W total) for GEM e4 vehicles

- Three 120W panels (360W total) for GEM e6 and eLXD models

Commercial-Grade Integration and Durability

Built specifically for fleet operators, this solar solution includes:

- A sleek, black anodized frame that slots into GEM’s existing roof rails

- Pre-engineered mounting holes for clean, secure installation—no drilling required

- A custom front guard for a polished, OEM-grade appearance

- Compatibility with both AGM and Li-ion batteries

- Seamless operation with standard 1kW or fast chargers—no need to disconnect solar

Maintenance is minimal. Thanks to the ETFE surface, panels naturally shed dust and dirt with rain or an occasional wipe-down.

Benefits of Solar-Powered GEM Vehicles

Extended range: Gain 4.3 to 12.4 miles of solar-powered range per day

Lower charging costs: Reduce reliance on grid power

Increased uptime: Charge passively while vehicles are parked

Operational efficiency: Minimize time spent rotating and plugging in vehicles

Sustainability visibility: Demonstrate clean energy commitment to stakeholders

Proven Performance in the Field

Since launch, commercial customers have experienced:

- Consistent solar performance in varied climates, including heat and humidity

- Fewer plug-in sessions and reduced strain on charging infrastructure

- Easier fleet management thanks to "set it and forget it" passive charging

Want to see how similar solar upgrades perform in other LSEVs? Check out our PowerDrive solution for golf cars and other LSEVs.

What's Next for GEM and PowerFilm Solar Integration

With strong initial success, we are continuing to expand this solar solution and plan to:

- Retrofit kits for legacy GEM vehicles

- Ensure compatibility with new battery technologies and vehicle models

Explore Solar for Your Electric Fleet

Whether you manage five LSEVs or fifty, solar charging is a smart, scalable upgrade. PowerFilm can help you reduce costs, extend range, and enhance your fleet’s sustainability with solar energy solutions for electric fleets.

Learn more and configure your GEM solar kit at: gemcar.com/solar

Interested in a custom solar solution? Contact us today

At PowerFilm, we don’t just make solar. We make solar work for you.

Take this blog post with you!