Harvesting indoor light energy is a viable power solution for many wireless sensors, trackers, and low-power devices used in a growing number of Internet of Things (IoT) applications.

Indoor photovoltaic (PV) modules provide a perpetual energy source that extends battery life, allows increased device functionality, and reduces battery bulk.

When considering a PV energy harvesting solution, the first step is evaluating your application environment.

Take this blog post with you!

Characterizing the following factors is essential to make sure your device remains charged.

-

Intensity

-

Daily Light Exposure

-

Shading

-

Mobility

-

Spectrum

Intensity

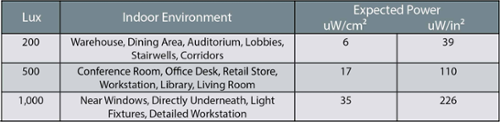

Light intensity, often measured in Lux, will significantly impact the power available to harvest in a given environment.

The table above shows light levels in several typical indoor environments and how much power you can expect a PV cell to generate.

As you can see, light intensity and power generation vary significantly across different lighting conditions. Warehouses and industrial areas are relatively dim compared to a bright retail space or workstations.

PowerFilm indoor PV modules are rated to operate between 200 and 1000 lux, making them well suited for most indoor lighting conditions.

Daily Light Exposure

Along with intensity, how long lights stay on each day or week is also a critical power factor.

In many retail, industrial, or manufacturing environments, lights will stay on 24 hours per day, allowing maximum time to collect energy. In comparison, residential or office settings may have much less light exposure each day.

It’s crucial to make sure the PV will collect enough energy while the lights are on to account for power consumed by the device when the lights are off.

Alternatively, devices in some applications only operate when lights are on. For these ideal cases, the PV only needs to collect enough energy to run the device in real-time and battery storage can be removed entirely.

Shading

Shelving, equipment, walls, furniture, and other objects can cause uneven shadows and lighting, which can greatly reduce output from a PV cell if not properly accounted for.

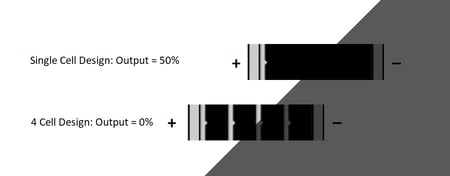

Most PV modules consist of multiple cells connected in series. During regular operation, all cells produce the same amount of electric current, which flows from one cell to the next until it reaches the battery or device.

Partially shading a module or cell dramatically reduces the current produced in that shaded area. This creates an electron log-jam, reducing the power produced by the entire panel to the level of the shaded area.

As shown in the figure above, designing with single-cell PV modules removes shading effects entirely. Since there is only one cell, no matter how the module is shaded, electrons will always have a way to get to the battery or device. This ensures the maximum amount of energy is always collected.

Mobility

Many devices used in IoT are not stationary. They may move from place to place, whether it be a wearable on a person or a tracker on a cart.

On top of uneven lighting, mobile devices are also more likely to experience rapid changes in light intensity. To handle this, a quick response MPPT algorithm is needed in the charging circuitry or charge controller, so that power collection is not interrupted by a change in light level.

Make sure to use a single cell PV design and an energy harvesting PMIC that can quickly adjust to changing light levels. This ensures the PV is always charging or providing power to the device.

Spectrum

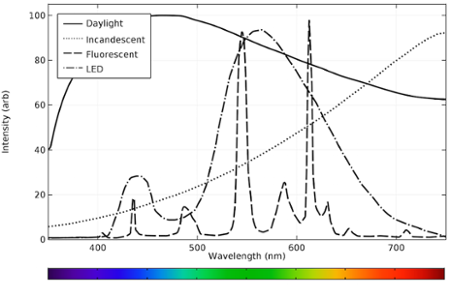

Finally, the spectrum of the indoor light source can affect the output of certain PV technologies. Most traditional PV materials are optimized for outdoor use under a solar spectrum that includes UV and near-infrared (IR) components.

Modern indoor light sources such as LEDs and fluorescents do not contain UV and IR light. A module with a 22% outdoor efficiency optimized to absorb light in these regions will typically produce less power than a module with 6% outdoor efficiency that absorbs principally in the visual spectrum. A module optimized to absorb over the entire UV, visual, and IR spectrum may not operate when UV or IR are removed.

PowerFilm’s Amorphous Silicon Indoor Light Series PV modules are optimized to collect low-intensity light from LED and fluorescent sources with guaranteed performance down to 200 lux.

Understanding these five factors is the essential first step of any energy harvesting solution and makes characterizing an indoor lighting environment simple.

If you have an application and aren’t sure if it is well suited for PV energy harvesting, reach out to us, and we can work through the process together.

Take this blog post with you!