Solar panels are typically made up of many cells connected in series, which increase the output voltage of the panel.

Multiple cells used to be a requirement when circuitry could not run on low voltage power sources, but with modern power management ICs (PMIC), this is no longer the case.

Designing a single-cell solar solution offers several key benefits over a multi-cell panel of the same dimensions.

Benefits:

-

Increased power efficiency

-

Higher performance on curved surfaces

-

Higher performance in irregular lighting environments

Let's dig a little deeper and see why using fewer cells, and ultimately a single cell can increase the performance of a solar solution.

Increased Power Efficiency

Every cell in a solar panel must be connected. This is accomplished using "inactive" strips of material between each cell. Since this material doesn't generate power, the more inactive area on a panel, the lower the overall efficiency.

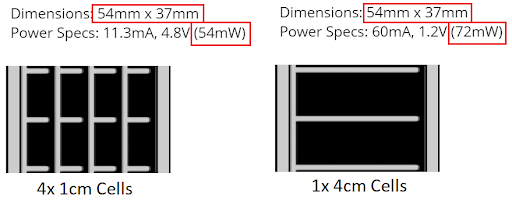

A panel with fewer cells requires less inactive space and will generate more power per area. The difference can be significant. The example shown below compares two panels with identical dimensions, one with four 1cm cells and the other with a single 4cm cell (Want to see what custom panel designs are possible? Check out our new custom solar design tool).

The single-cell panel produces 72mW of power, a 33% increase compared with the 54mW produced by the four-cell design.

This simple design change has an enormous impact on panel performance, which can be vital for applications that need every mW of power they can get.

The single-cell design has a lower output voltage, 1.2V, but this is no problem for modern energy harvesting PMIC, which can operate efficiently below 1V.

Not only does the single-cell panel produce more power, but it can also greatly simplify the design process as well.

Higher Performance on Curved Surfaces

One great benefit of PowerFilm's flexible thin-film solar material is that it can contour to curved surfaces, such as wrapping around a pole.

First, let's understand the problem curved surfaces introduce to multi-cell panels.

For panels with multiple cells, total power output is limited by the cell that is producing the least power. If not accounted for, this can be a big problem for panels installed on curved surfaces.

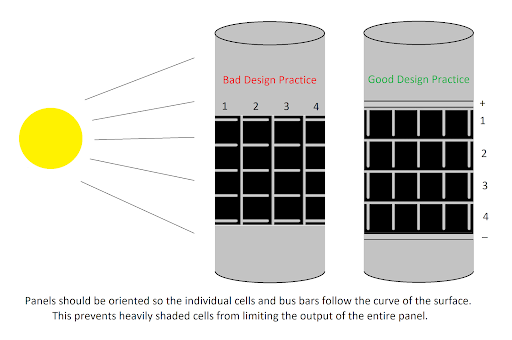

This problem is demonstrated in the diagram below, which shows the correct (right) and incorrect (left) ways to install a multi-cell panel on a curved surface.

The root problem is unequal illumination between cells.

Cells on the left panel (bad design) are oriented perpendicular to curve around the pole. Cell #1 is fully illuminated, while cell #4 is heavily shaded. Even though half of the panel may be well illuminated, the entire panel output will be limited by cell #4 and will perform as if the whole panel is heavily shaded.

Cells on the right panel (good design) are oriented in parallel to curve around the pole. This keeps all cells illuminated equally, and no single cell will limit the entire panel. In this configuration, if half the panel is shaded, the panel output will only drop by half.

For single-cell panels, this problem is non-existent. No matter how it is oriented, the performance will be the same. It is impossible to have unequal illumination between cells if there is only one cell.

This makes a single cell very attractive for curved surface applications and for applications with irregular lighting.

Higher Performance in Irregular Lighting Environments

Uniform lighting is a luxury that isn't always available. Shading can be complicated to predict, especially for indoor IoT applications where devices may be installed on walls, moved around a warehouse, or on a wearable.

Similar to curved surfaces, irregular shading can significantly reduce the performance of multi-cell solar panels. Again, a single heavily shaded cell can make the panel perform as if it is completely shaded.

Single-cell designs do not suffer from this problem. The output is proportional to the amount of panel illuminated. If 25% is completely blocked, the output will only drop by 25%.

The pattern of shading, which can affect the performance of unshaded areas on multi-cell panels doesn’t affect the performance of the un-shaded regions of single-cell panels.

Designing with Single-Cell Panels

Now that we understand the benefits of single-cell solutions, how can they be used to power electronics?

The key is using the proper energy harvesting PMIC. A PMIC can handle the low input voltage of a single cell panel, and boost it up to charge a battery or run standard circuitry.

TI, e-peas, and Analog Devices are several companies offering low power PMIC solutions that work well with single-cell solutions. Next-generation PMIC technology, Nowi Energy, is right around the corner, making energy harvesting solutions even higher performance and more feasible.

To start prototyping, check out PowerFilm's Solar Development Kits, which use TI's BQ25570 PMIC and come configured to charge lithium battery chemistries.

Although we don't currently have any standard single-cell panel designs (in the works), contact us, and we can work through prototyping options.

Although multi-cell panels used to be a requirement when designing solar-powered electronics, modern PMIC enables single-cell designs to be possible.

Single-cell solutions offer several significant advantages over multi-cell panels including, higher power efficiency, better performance on a curved surface, and better performance in variable lighting conditions.

If you would like to learn more about PowerFilm's solar solutions, please contact us. We can answer questions, review an application, or start the custom design process.

With over 30 years of experience providing custom solar for IoT and remote power spaces, we will ensure you have the best solution for your application.